How to Choose the Right FRP Resin for High-Performance Industrial Applications

Fiberglass Reinforced Plastic (FRP) has transformed how industries build and protect infrastructure. Its lightweight strength, corrosion resistance, and adaptability make it ideal for everything from chemical plants to marine docks, pipelines, cooling towers, and automotive components. But the true performance of FRP depends on one critical factor: the resin used in the composite.

The right FRP Resin contributes to long operational life, safety, and reduced maintenance costs. The wrong resin can lead to early cracking, environmental damage, or total structural failure. Understanding how to choose the right resin is not just helpful - it is essential for industrial success.

Why Resin Matters So Much in FRP

Resin frp material helps with bonding that holds reinforcing fibers together. It gives the final product:

- Strength and load-bearing capability

- Protection from water, moisture, and UV light

- Chemical resistance in corrosive environments

- Dimensional stability in varying temperatures

- A smooth, sealed surface finish

The resin decides whether FRP survives harsh industrial challenges or breaks under conditions it wasn’t designed for.

The Main Types of FRP Resin Used in Industry

Three primary resin types dominate FRP manufacturing. Each has different abilities and ideal applications.

Polyester Resin – Reliable for Standard Conditions

Polyester resin is the most widely adopted because of its balance between performance and affordability. It provides good mechanical strength for products that operate in normal environmental conditions.

Common uses include:

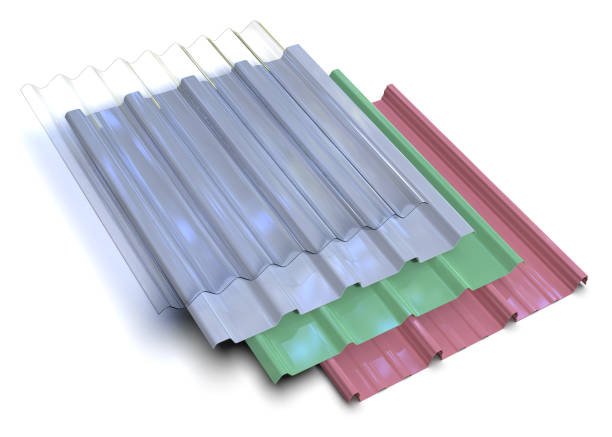

- Roofing sheets and structural panels

- Cooling tower parts

- General-use pipes and ducts

- Non-critical water storage tanks

Average lifespan: 10–15 years depending on exposure

Polyester is economical and practical, but not strong enough for environments involving strong chemicals or high heat.

Vinyl Ester Resin – For High-Corrosion Areas

Vinyl ester resin is a stronger and more corrosion-resistant upgrade over polyester. It handles environments where chemical exposure and moisture are constant risks.

Industrial uses include:

- Chemical processing tanks and scrubbers

- Wastewater and desalination equipment

- Marine structures and offshore components

- Corrosion-resistant pipelines

Average lifespan: 20–25 years with proper installation

If the product will face chemicals, vinyl ester offers far better protection and durability.

Epoxy Resin – Superior Structural Strength

Epoxy resin offers the highest strength, adhesive bonding, and resistance to stress. It is the right choice when safety, structural integrity, and long-term reliability are the highest priorities.

Best suited for:

- Aerospace-grade components

- High-pressure pipelines

- Protective FRP coating on steel structures

- Critical automotive and transportation parts

Average lifespan: 25–40 years depending on usage conditions

This makes epoxy the top choice for industries where equipment failure is not an option.

How to Select the Right Resin: Key Decision Factors

Choosing a resin should never be based on price alone. Matching performance requirements with environmental conditions ensures long-term success.

Environmental Conditions: Where Will It Be Used?

Exposure to chemicals, saltwater, industrial fumes, UV light, or extreme weather can degrade FRP over time.

- Normal exposure → Polyester works well

- Constant chemical or marine exposure → Vinyl ester is safer

- Heavy-duty environments → Epoxy ensures optimal durability

Understanding the surroundings helps prevent early breakdown.

Structural Requirements: How Much Stress Will It Handle?

Consider the level of:

- Pressure

- Vibration

- Movement

- Mechanical load

Applications like pipelines, load-bearing components, and high-impact zones demand epoxy for strength and durability.

Manufacturing Process: What Is the Production Method?

Different fabrication techniques require different resin properties. Hand lay-up, pultrusion, vacuum infusion, and filament winding all need specific curing speeds and flow behavior. Choosing the wrong resin may affect production efficiency and structural performance.

Budget and Lifespan Expectations

Industrial decision-making always considers cost but focusing only on upfront savings can be misleading. A more durable resin often results in lower repair and replacement expenses later.

- Polyester = lowest cost / 10–15 years lifespan

- Vinyl ester = moderate cost / 20–25 years lifespan

- Epoxy = highest cost / 25–40 years lifespan

If the failure of a structure could lead to operational disruption or safety issues, investing in the stronger resin becomes the most cost-effective long-term choice.

Choosing Resin the Right Way

The best FRP Resin is always the one aligned with:

- The operating environment

- The expected stress and load

- The fabrication process

- Budget versus required lifespan

Before finalizing, evaluating these criteria ensures that your FRP product performs reliably and delivers lasting industrial value.

Work With Trusted Resin Suppliers for Guaranteed Performance

Material quality directly influences long-term performance. When sourcing for infrastructure, heavy-industry equipment, or corrosive-zone applications, partnering with experienced suppliers makes a measurable difference.

MB Enterprises, renowned as the top frp materials company, provides high-performance resin solutions for bulk and large industrial projects - ensuring your FRP products deliver maximum durability and safety in real-world operations.

FAQ

1. How do I choose the right FRP Resin?

Focus on where the resin FRP material will be used and the load it must handle. FRP resin like polyester works for normal use, vinyl ester suits corrosive areas, and epoxy delivers maximum strength.

2. What happens if the wrong resin is selected?

Making a poor choice can weaken FRP products further, causing cracks, corrosion, and expensive maintainence.

3. Which resin works best for chemical or water-based applications?

Vinyl ester is usually preferred as a FRP coating or for tanks exposed to chemicals, moisture, or saltwater.

4. Is epoxy a good choice for structural components?

Yes. Epoxy offers excellent bonding and long-term durability - ideal for FRP rebar and rebar epoxy applications where safety and load strength are critical.

5. Does the manufacturing method affect which resin I should use?

Absolutely. Processes like pultrusion, winding or vacuum infusion need resins that match their curing and flow behavior for the best FRP products performance.

6. Why should I work with a trusted FRP materials company?

A reliable supplier ensures quality resin FRP material and expert guidance - helping you get durable, corrosion-resistant solutions that last.

-2462x2317.png)

15 Comment(s)

Thank you a bunch for sharing this with all folks you really recognise what you are speaking about! Bookmarked. Please also talk over with my website =). We could have a link change agreement among us!

There is definately a lot to learn about this subject. I love all the points you have made.

I enjoy what you guys are up too. This kind of clever work and coverage! Keep up the amazing works guys I've included you guys to my blogroll.

Your means of explaining the whole thing in this article is in fact fastidious, all be able to easily understand it, Thanks a lot.

I will immediately snatch your rss as I can’t find your email subscription link or newsletter service. Do you have any? Kindly permit me know in order that I may just subscribe. Thanks.

Everything is very open with a clear description of the challenges. It was truly informative. Your website is extremely helpful. Thanks for sharing!

I will right away grasp your rss feed as I can not find your e-mail subscription hyperlink or newsletter service. Do you have any? Kindly let me know in order that I could subscribe. Thanks.

What's up to every body, it's my first go to see of this web site; this blog consists of amazing and genuinely good data in favor of visitors.

Hola! I've been following your website for a while now and finally got the bravery to go ahead and give you a shout out from Atascocita Texas! Just wanted to tell you keep up the good job!

It's very straightforward to find out any topic on net as compared to textbooks, as I found this post at this website.

Perfect piece of work you have done, this website is really cool with good info.

I’ll right away snatch your rss as I can’t find your email subscription hyperlink or e-newsletter service. Do you have any? Kindly let me recognise in order that I could subscribe. Thanks.

I like what you guys are usually up too. This kind of clever work and reporting! Keep up the very good works guys I’ve added you guys to my personal blogroll.

These are really great ideas in on the topic of blogging. You have touched some pleasant points here. Any way keep up wrinting.

Hi, I do think this is an excellent web site. I stumbledupon it ;) I will come back once again since i have book marked it. Money and freedom is the greatest way to change, may you be rich and continue to help other people.

Leave a Comment